Siemens Turbomachinery HV Turbo Blowers from IBS Blowers

A good worker never blames his tools. In addition, a good worker always knows how to pick the right tools to use. Choosing the correct equipment to support your business will go a long way towards keep your business up and running and lowering the risk of downtime. From the very moment that your vacuum pumps fails to operate correctly, your business starts losing money. Industrial Blower Services provides an extensive collection of Siemens Turbomachinery HV Turbo Blowers; industrial vacuums and Robuschi Liquid Ring Vacuum Pumps high quality, at affordable prices, so that of all of the aspects of your business that you have to concern yourself with, failing equipment is not one of them.

Vacuum technology is synonymous with the Industrial, Utility, Manufacturing, and Municipal sectors of industry used for a number of varied and specified industrial applications. IBS’s industrial and engineering experts in vacuum technology and its respective applications, can advise you as to what specific type of equipment would work best for your company and which applications and processes would most benefit from the utilisation of this equipment.

Dedicated staff at IBS have years of experience in the manufacturing, chemical and other industries and so know from first-hand knowledge what works best in which environment. IBS experts can assist customers in making that critical decision of which equipment would be the most suitable for their needs to maximise operations, optimising costs and effectively resulting in a positive return on investment. IBS is renowned for stocking a large range of superior makes and models of vacuum pumps and blowers, chosen by well-known brands to be their sole-provider of certain products in the UK. IBS will also never sacrifice quality to save costs however will always be able to offer a suitable alternative for those who may be in need of assistance, where budget considerations can be made. Customers can revert to the engineers at IBS for advice from everything regarding maintenance and repairs, servicing, evacuation times, vacuum levels and volumes, to blower spares and ancillaries, to operational costs and environmental aspects.

Initially named the “water ring pump” the liquid ring vacuum pump is used for creating vacuum in moist gases and vapours. Typically utilised in the chemical industry, liquid ring vacuums, like many other vacuum systems, operate on the principle of positive displacement of liquid, channelling the liquid in a piston-like fashion to achieve displacement. Operating a relatively low temperatures liquid ring vacuum pumps are ideal for the condensation of vapours essentially allowing them to function, in part, as condensers, drastically reducing volume. Adaptable in that they are able to fit the medium which is being pumped, the liquid ring pump offers excellent benefits in that the lower operational temperatures, allows for the successful for the pumping of polymers which are especially temperature sensitive and prove to be far less problematic when involved in the pumping of the more volatile materials.

RVS Liquid Ring Vacuum Pumps

The RVS series comprises single stage block model machines. They are used in the fields of sterilisation, concentration, dying, impregnation, plastic extrusion, degassing and extraction of non-condensable gas from condensers in the chemical, pharmaceutical, food, pulp and paper, sugar and textile industries in addition to applications in power plants and hospitals.

The RVS series has the following key features.

- Vacuums up to 33 mbar A

- Suction capacity up to 4200 m3/hour

- Able to pump gasses and vapours

- No lubricant in contact with the pumped gasses

- Able to work in numerous applications with appropriate choice of construction materials and service fluid

RBS/AV Vacuum Boosters

The RBS/AV positive displacement machines are utilised as boosters to increase vacuum levels when used in series with a primary vacuum unit.

Typical fields of application include automotive, food, pharmaceutical, chemical, electronic and aerospace industries and power plants.

The RBS/AV series has the following key features.

- Vacuum levels of 0.01 to 20 mbar absolute

- Suction capacities from 300 to 8800 m3/hour

- Able to pump gasses and vapours

RB-DV Pre-inlet Vacuum Pumps

The RB-DV series includes tri-lobe positive displacement machines that have an atmospheric pre-injection device which reduces the heating of the gas and the power absorbed by the machine. This allows for vacuum levels up to 93% without the need for additional water injection or heat exchanger.

Typical areas of application include conveying and distribution of granulated materials in the chemical and pharmaceutical industries, de-aeration plants and centralised packaging, handling and processing machines.

The RB-DV series has the following key features.

- 93% vacuum on closed line, 90% continuous

- 840 to 10,500 m3/hour nominal capacities

- Able to pump gasses and vapours

- No oil mist

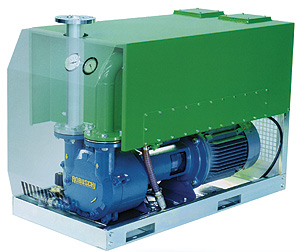

Robuschi Green Box

Environmentally friendly

An example of Robuschi innovative tradition utilising a liquid ring vacuum unit in either oil or water versions which is:

An example of Robuschi innovative tradition utilising a liquid ring vacuum unit in either oil or water versions which is:

- Compact

- Low noise

- Able to reach 15 mbar vacuum

- Ready for use

- Minimum maintenance

Amphitec Base Loaders ®

IBS has been the industry leader for over 30 years and their main objective is to meet their customer’s expectations and requirements by understanding their equipment and processes. With this in mind, IBS are constantly expanding their product offering to keep up with the industry demands and innovative products.

IBS are making their mark in the Industry with their large selection of vacuum loaders and root type blowers and agents for many well-leading Industry brands throughout the UK & US such as Amphitec Vortex Loaders®.

The Amphitec Base Loader ® is the latest, economical solution for suction, blowing and transporting dry products and liquids.

Amphitec Base-Loader® characteristics

- Vacuuming, discharging and transporting dry and wet products

- 12,5 m³ stainless steel product tank

- Suction with 9000 m³/hour, max. 96% vacuum

- High payload due to empty weight of approx. 15500 kg

- Easy to operate and maintain

- Maximum manoeuvrability by short wheel base (3900 mm)

The Amphitec range have many products are: Amphitec Flex-Loader G3 is the 3rd generation movable, self-supporting, industrial pressure vacuum installation and offers the flexible solution for suction, blowing and transporting.

The Amphitec Max-Loader G2 is an industrial semi-trailer for suction and blowing of dry products and liquids. Completely self-supporting and can be used with any tractor unit.

Speak to IBS today for their full range of products.

IBS are the sole European distributors of Fuitland Vacuum pumps

IBS are market leaders in innovative Industrial Services equipment and solutions. They have a reputation as leaders in cutting edge technology for Industrial Blower Equipment such as Fruitland Vacuum Pumps and Industrial Vacuum Services which are known for their high performance, robust equipment, cost effective and versatility. So versatile they vacuum wet and dry spillage and dust right through.

Have a look at some of the features below of IBS product range and service offering -

Liquid ring vacuum pumps are a single stage block model, suitable to compress gas and vapours in the industrial processes.

The main features are:

- able to pump gases and vapours;

- nearly isothermal compression of gases;

- no lubricant in contact with pumped gas;

- the pumps must be continuously fed with service liquid, normally water (oil, organic liquids etc. can be used), while working in a sufficient rate to eliminate the heat produced by the compression of gases and to replace any liquid which flows out of the pump together with the gas. The service liquid can be separated from the gas in a liquid separator and can be recirculated either partially or entirely, after intermediate cooling;

- safe operation and minimum maintenance;

- Reduced noise and vibration.

The liquid ring vacuum pumps range includes the following sizes:

- RVS 3÷16 /M directly coupled to the flange of an electric motor and the impeller is supported by the electric motor standard bearings;

- > RVS 17÷21 /SG are supported by a bearing support with two sealed bearings life lubricated with grease;

- RVS 23÷60 /CT bearing support with bearings grease lubricated.

Wastes collection by portable vacuum power

IBS Ltd offer a comprehensive solutions for vacuuming wet and dry spillage and dust through the use of their extensive industrial vacuum loaders. IBS offer a simple and effective portable air conveying system for cleaning, recycling, collecting waste and split product.

Fully portable by forklift and therefore suitable for material collection anywhere on site in all industrial and commercial applications, IBS offer a wide range of Industrial vacuum loaders. (Industrial Vacuum Machines)

Example of a portable industrial vacuum pump unit:

FVP 25 Portable Heavy Duty High Performance Industrial Vacuum Loader.

Able to collect a range of materials including fine particles through to aggregates up to 50 mm in size, the unit has a maximum loading rate of 3 tons per hour over 40 meters or further if utilised with a vacuum interceptor skip and fixed pipework system.

No obligation site surveys. Units available for trial purposes.

Units can also be supplied on short or long term hire, contract hire or lease.

The FVP 25 has been designed for:

High performance

- Excellent conveying rates

- Utilises an energy saving electric motor on soft start (running on a 32A power

supply) and a high quality tri-lobe positive displacement vacuum pump - Quiet operation

- Excellent filtration

Build quality and reliability

- Very robust - exceeds that of our competitors whilst remaining very cost effective

- Low running and maintenance costs

Versatility

- Unlike our competitors machines the FVP25 is suitable for wet and dry materials and sludges

- Super flexible hose and a selection of vacuum tools are available

Adaptability

- The FVP25 can be used to power a centralised vacuum system

to feed material back into the process or for bagging purposes.

Portability

- The unit has 1 cubic meter integral tipping skip

Productivity

- The FVP25 can be supplied with an additional 1 cubic meter fork lift

intercept sealed skip, bottom dump intercept hopper or filter hopper.

Larger skips are also available.

Get your vacuum loader health checked for FREE!

Searching for a company that repairs industrial equipment, I came across IBS Blowers - Industrial Blower Services based in the UK serving the industry with Industrial Vacuum Services and Industrial Vacuum Loader ; impressively they have recently expanded and opened offices in America; for information about their global expansion view IBS Blowers UK and IBS Blowers USA.

Amazingly not many companies these days offer anything for free however, IBS offer a FREE HEALTH CHECK for Industrial Vacuum Loader they offer which is exactly the service our company requires from time to time. I completed the quick and easy form and within no time at all, assistance for the Free Health Check was on offer.

No hidden costs involved or any pressure a genuine offer from IBS Blowers – take advantage you have nothing to lose.

-large.jpg) Offering a variety of engineering services makes IBS a versatile one-stop-shop providing convenience to clients, as well as quality products. Services include processing engineering services, repairs, servicing and recondition of blowers, vacuums and pumps which can be done both on and off-site, site surveys and fault finding, metal spray painting and equipment hire of various shaft and blower sets, vacuum pumps and portable vacuum units.

Offering a variety of engineering services makes IBS a versatile one-stop-shop providing convenience to clients, as well as quality products. Services include processing engineering services, repairs, servicing and recondition of blowers, vacuums and pumps which can be done both on and off-site, site surveys and fault finding, metal spray painting and equipment hire of various shaft and blower sets, vacuum pumps and portable vacuum units.