IBS | Hire Heavy Duty Industrial Vacuum

IBS Industrial Blower Services has an impressive range of blowers, vacuums and pumps available to manufacturers in the industrial and other sectors. As suppliers, IBS is well known for its products and related service options and is considered UK’s premium go-to when it comes to pumps, blowers and vacuums. The manufacturing environment is a competitive one so its imperative that businesses consider quality industrial equipment to support their on-going success.

There are 3 types of vacuum pumps of which the most popular is the positive displacement pump, with momentum transfer pumps and entrapments pumps being subsidiaries to the positive displacement pump. While momentum (also known as molecular) pumps use a intense jets of fluid or high paced rotating blades to remove gas molecules of out a chamber, alternatively entrapment vacuum pumps utilise lower temperatures to decrease a gas molecules size thereby trapping the gases into a absorbent or even solid state within a chamber. Positive displacement pumps make use of technology, which moves fluids or liquids through the pump chamber by increasing the cavity on the suction side of the vacuum and discharging the fluid as the cavity collapses. There are two types of positive displacement vacuum pumps, the first being reciprocating positive displacement pumps, the technology of which you will find commonly in piston pumps. And the second being the rotary positive displacement pump of which liquid ring pump and sliding vane rotary pump are common examples

As robust as the vacuum pump can be, there will be occasions, which result in a call for hiring of an industrial vacuum pump. Some businesses prefer to hire their vacuum pumps for short periods where the need arises. Other businesses may be under-going maintenance and servicing and as such would require replacement vacuum pumps to avoid downtime of production. New businesses who are not yet sustainable enough to purchase large industrial equipment prefer not to make the initial purchase and revert to hiring the desired, requisite equipment. In order Hire Heavy Duty Industrial Vacuum, companies can contact IBS professional engineers for advice on how best to proceed with their vacuum pump set up, requirements and suitable options.

In the event of a breakdown IBS have liquid ring, rotary vane, side channel, claw and roots type vacuum pumps available. For Wet Industrial Vacuuming Hire the range for hire provides volume flow rates between 4 and 1500 m3/hour FAD. Typical areas where Dry Industrial Vacuuming Hire would need to be considered is in industries such as the production of dry food products, or packaging, conveying and printing applications. When accidental damage occurs, all units are units based in UK locations for fast delivery to site.

Portable Vacuum Loader hire options include both wet and dry industrial vacuuming equipment hire as well as air Industrial Vacuuming and portable air conveying system hire. IBS Industrial Blower Services will also make repairs or service and recondition blowers, vacuums and pumps ensuring that you enjoy the full life-span of your industrial equipment.

Portable Industrial Vacuum Units from IBS

Vacuum pump technology was first utilised since the first champions of the industrial revolutions brought this technology, the brainwave of scientist Otto von Guericke, into existence. Developed and improved upon to create what has become one of the fundamental building blocks of industry in the modern era, with its hundreds of applications in several different industry sectors, vacuum technology has been said to be endlessly evolving, proving it one of the most critical invention of all the industrial revolutions. With the 4th Industrial Revolution in full swing, is there still a future for this type of technology in industry or are we looking at the end of an era for this science-based technical tool?

IBS has been in the vacuum blower industry for more then 3 decades and believes that from a current economic stance on business, the application of vacuum pump technology plays as important a role as ever before and that there no signs of this trend waning in the near future. Certainly, the current application of the use of vacuum technology in retail, manufacturing and everyday packaging industries, such as plastic molding, washing systems in food processing, underwater aeration with commercial and household applications, PET coating on plastic bottles and dry freezing of packaged food and beverages, is a going concern. However, as the call for safer and more environmentally friendly, sustainability becomes the focus of growing concerns for the health and well-being of the globe and humanity itself, will we begin to see a decrease in the use of vacuum technology?

The answer is a simple no. More and more, it becomes evident that vacuum technology is here to stay. Although common applications may well change due to the changing demands from governments to make swift and steady changes towards sustainable business, vacuum technology is already being tested and proving vital in the developments of the 4IR. It is predicted that we will witness vital incremental improvements on seals and gauges, calibration methods with far superior accuracy will appear and even more specialised custom-designed vacuum facilities being created to accommodate rings, reactors, and portable industrial vacuum units. Side Channel Blowers and industrial Vacuum units stand to be developed as new products begin to appear as the market begins to adapt with the introduction of solid-state electronics.

The prediction is that the vacuum pumps of the near-future will not only be more reliable with the capacity for vastly improved operations for distinctly longer periods of time, but will also prove themselves to be vital to the development of lasers, superconductors, catalysis as well as solar energy, microprocessors and computers. While it is hard to know for sure the exact developmental path of vacuum technology, it would be premature to begin a move away from what may be viewed as a technology whose time has come.

The prediction is that the vacuum pumps of the near-future will not only be more reliable with the capacity for vastly improved operations for distinctly longer periods of time, but will also prove themselves to be vital to the development of lasers, superconductors, catalysis as well as solar energy, microprocessors and computers. While it is hard to know for sure the exact developmental path of vacuum technology, it would be premature to begin a move away from what may be viewed as a technology whose time has come.

IBS Blowers is excited to be in an industry, which is crucial to the growth and development of industry and will continue to provide a vast array of products, both new and reconditioned, which can be recommended with confidence from now into the future.

Siemens Turbomachinery HV Turbo Blowers from IBS Blowers

A good worker never blames his tools. In addition, a good worker always knows how to pick the right tools to use. Choosing the correct equipment to support your business will go a long way towards keep your business up and running and lowering the risk of downtime. From the very moment that your vacuum pumps fails to operate correctly, your business starts losing money. Industrial Blower Services provides an extensive collection of Siemens Turbomachinery HV Turbo Blowers; industrial vacuums and Robuschi Liquid Ring Vacuum Pumps high quality, at affordable prices, so that of all of the aspects of your business that you have to concern yourself with, failing equipment is not one of them.

Vacuum technology is synonymous with the Industrial, Utility, Manufacturing, and Municipal sectors of industry used for a number of varied and specified industrial applications. IBS’s industrial and engineering experts in vacuum technology and its respective applications, can advise you as to what specific type of equipment would work best for your company and which applications and processes would most benefit from the utilisation of this equipment.

Dedicated staff at IBS have years of experience in the manufacturing, chemical and other industries and so know from first-hand knowledge what works best in which environment. IBS experts can assist customers in making that critical decision of which equipment would be the most suitable for their needs to maximise operations, optimising costs and effectively resulting in a positive return on investment. IBS is renowned for stocking a large range of superior makes and models of vacuum pumps and blowers, chosen by well-known brands to be their sole-provider of certain products in the UK. IBS will also never sacrifice quality to save costs however will always be able to offer a suitable alternative for those who may be in need of assistance, where budget considerations can be made. Customers can revert to the engineers at IBS for advice from everything regarding maintenance and repairs, servicing, evacuation times, vacuum levels and volumes, to blower spares and ancillaries, to operational costs and environmental aspects.

Initially named the “water ring pump” the liquid ring vacuum pump is used for creating vacuum in moist gases and vapours. Typically utilised in the chemical industry, liquid ring vacuums, like many other vacuum systems, operate on the principle of positive displacement of liquid, channelling the liquid in a piston-like fashion to achieve displacement. Operating a relatively low temperatures liquid ring vacuum pumps are ideal for the condensation of vapours essentially allowing them to function, in part, as condensers, drastically reducing volume. Adaptable in that they are able to fit the medium which is being pumped, the liquid ring pump offers excellent benefits in that the lower operational temperatures, allows for the successful for the pumping of polymers which are especially temperature sensitive and prove to be far less problematic when involved in the pumping of the more volatile materials.

RVS Liquid Ring Vacuum Pumps

The RVS series comprises single stage block model machines. They are used in the fields of sterilisation, concentration, dying, impregnation, plastic extrusion, degassing and extraction of non-condensable gas from condensers in the chemical, pharmaceutical, food, pulp and paper, sugar and textile industries in addition to applications in power plants and hospitals.

The RVS series has the following key features.

- Vacuums up to 33 mbar A

- Suction capacity up to 4200 m3/hour

- Able to pump gasses and vapours

- No lubricant in contact with the pumped gasses

- Able to work in numerous applications with appropriate choice of construction materials and service fluid

RBS/AV Vacuum Boosters

The RBS/AV positive displacement machines are utilised as boosters to increase vacuum levels when used in series with a primary vacuum unit.

Typical fields of application include automotive, food, pharmaceutical, chemical, electronic and aerospace industries and power plants.

The RBS/AV series has the following key features.

- Vacuum levels of 0.01 to 20 mbar absolute

- Suction capacities from 300 to 8800 m3/hour

- Able to pump gasses and vapours

RB-DV Pre-inlet Vacuum Pumps

The RB-DV series includes tri-lobe positive displacement machines that have an atmospheric pre-injection device which reduces the heating of the gas and the power absorbed by the machine. This allows for vacuum levels up to 93% without the need for additional water injection or heat exchanger.

Typical areas of application include conveying and distribution of granulated materials in the chemical and pharmaceutical industries, de-aeration plants and centralised packaging, handling and processing machines.

The RB-DV series has the following key features.

- 93% vacuum on closed line, 90% continuous

- 840 to 10,500 m3/hour nominal capacities

- Able to pump gasses and vapours

- No oil mist

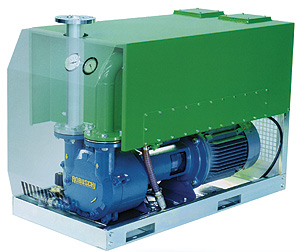

Robuschi Green Box

Environmentally friendly

An example of Robuschi innovative tradition utilising a liquid ring vacuum unit in either oil or water versions which is:

An example of Robuschi innovative tradition utilising a liquid ring vacuum unit in either oil or water versions which is:

- Compact

- Low noise

- Able to reach 15 mbar vacuum

- Ready for use

- Minimum maintenance

At IBS Ltd offer you a comprehensive solution for Industrial Vacuum units

With a deep understanding and knowledge of your industry, IBS is not only your best answer for a business partner, but ultimately forms an essential part of your business, as if they were one the same as you. No one product which a company would require, in any industry from the food and beverage industry to the chemical and pharmaceutical industries, could not be made available to your business as soon as it were needed and every vacuum and blower, pump and compressor currently used in your company can be repaired by IBS. Being part of the manufacturing industry means that there is zero time for downtime during your week, which is why it is of the utmost importance that these products are available to you.

This dedicated group of process engineers possess the knowledge which allows them to assist with all a business’s processing needs, from start to finish. Whether it be performing the initial site survey report, or developing and running a turnkey project until conclusion, IBS offers it all.

Services range from and include: site surveys, plant reports, design (including PLC and SCADA design and implementation with optional online support) installation, full contract management services, upgrading and automation of existing processes and plants, servicing (single visit or term contract basis) and complete site rewiring services, to the very latest wiring and electrical standards.

IBS can offer a complete refurbishment of any existing plant which includes new or Industrial Vacuum units, Side Channel Blowers, diverters and sifters; fault sourcing for servicing purposes or for a complete over-haul; Silo relocation and refurbishment; fluidisation packages including blowers, solenoid valves, fluidising tiles, pipework and valves as well as full electrical refurbishments. Reconditioned blowers are guaranteed to be in near-new condition. Equipment and parts are obtained from plants who longer require the equipment, or who have upgraded their industrial equipment. IBS then has license from the original suppliers to refurbish the pieces for re-sale which allows IBS to pass on a considerable saving in terms of cost, especially for new-comers to the industry or for business who are unable to afford to replace old, worn out blowers and vacuums, with new ones.

Besides providing a vast range of new industrial equipment, IBS repairs, services and reconditions everything including compressors, road tanker equipment, filers, valves and seals, and pumps. Portable vacuum units are a favourite for repair and reconditioning, for example to the FVP25 portable vacuum unit, as well as other manufacturing machines. A full servicing workover includes the changing filter and seals, changing of vacuum pump oil, checking vacuum relief valves for wear and tear and replacing where necessary, checking of the electrical circuits and its components to identify weaknesses and identify risk caused by constant use and checking and re-tensioning or replacing of drive belts.

Trusting IBS with the servicing, repair and reconditioning of your industrial equipment can save your company by ensuring that equipment is functioning correctly, avoiding unexpected break-downs and loss of production hours which may result in lack of client trust or loss of project and income, and can also save money should the general economy cause you to fall short of your annual financial goals. You need look no further than IBS process engineers for 100% of your business’s industrial needs.

IBS stock Robuschi Liquid Ring Vacuum Pumps

Industrial Blower Services (IBS) has been operational for more than 30 years and during this time, not only have we become UK’s largest supplier of both new and reconditioned blowers but we have also become experts in our field. IBS provides services extensively across the UK and our clients range vastly, from those in the manufacturing industry to the mining and petrochemical industries and the like. Most Industries, including Food, Beverage, Paper, Health, Water, Packaging, and Pneumatic Conveying require industrial blowers for their manufacturing.

What sets IBS apart however, is that we understand that any machinery downtime is going to cost your business severely. We acknowledge and understand the importance of keeping your factory operational and producing consistently, in order to achieve your manufacturing commitments. All machines, when not properly serviced, will eventually suffer with wear and tear, run down and eventually begin to fail. While servicing your machinery can slow your production down and cost your business, this is in no way comparable to the loss of time, money and production which will occur if your blowers fail to operate during production periods. IBS understands the importance of quality machinery and blowers and fans are an integral part of your production.

In an industry where manufacturing of equipment can take months to produce, we are proud to hold the largest fleet of equipment for hire. Whether it is for a short or a long term project, or just to provide you with a back-up when your own equipment failed you as a result of wear and tear, we can assist you in these emergency or planned situations. Products such as the Zepher blowers, Siemens blowers, and Robuschi blowers are ready at a moment’s notice for collection or drop-off at your site. IBS also has a team of experienced engineers to provide on-site services and technical assistance.

At IBS, we have confidence that our growth as a company as well as our reputation as a reliable service provider comes as the result of our uncompromising approach to customer service. Excellent customer service is the blood line of our business, so not only do we provide you with the products and the services, that we are confident are the very best for your business, but we are also committed to forming relationships with our customers by ensuring that we do what we say we will do each and every time. By doing so, we guarantee efficiency irrespective of the projects nature or size.

Amphitec Base Loaders ®

IBS has been the industry leader for over 30 years and their main objective is to meet their customer’s expectations and requirements by understanding their equipment and processes. With this in mind, IBS are constantly expanding their product offering to keep up with the industry demands and innovative products.

IBS are making their mark in the Industry with their large selection of vacuum loaders and root type blowers and agents for many well-leading Industry brands throughout the UK & US such as Amphitec Vortex Loaders®.

The Amphitec Base Loader ® is the latest, economical solution for suction, blowing and transporting dry products and liquids.

Amphitec Base-Loader® characteristics

- Vacuuming, discharging and transporting dry and wet products

- 12,5 m³ stainless steel product tank

- Suction with 9000 m³/hour, max. 96% vacuum

- High payload due to empty weight of approx. 15500 kg

- Easy to operate and maintain

- Maximum manoeuvrability by short wheel base (3900 mm)

The Amphitec range have many products are: Amphitec Flex-Loader G3 is the 3rd generation movable, self-supporting, industrial pressure vacuum installation and offers the flexible solution for suction, blowing and transporting.

The Amphitec Max-Loader G2 is an industrial semi-trailer for suction and blowing of dry products and liquids. Completely self-supporting and can be used with any tractor unit.

Speak to IBS today for their full range of products.

Siemens Turbomachinery HV Turbo Blowers from IBS

IBS leaders in Industrial Blower Equipment, and what sets them apart from their competitors? Each member of this innovative team of people ensures they uphold their mission and collectively they ensure their clients have no unnecessary downtime. The cover all sectors across many industries and proud agents for many leading brands of Portable Industrial Vacuum Units and HV Turbo Blowers such as Siemens Turbomachinery HV Turbo Blowers.

Robuschi Liquid Ring Vacuum Pumps

Blackmer Sliding Vane Vacuum Pumps

Elmo Rietschle

Siemens Turbomachinery HV Turbo Blowers

Zephyr

Howden Compressors

Sulzer

Hoffman

Site Visits and Support

IBS have a team of experienced engineers to provide on-site services and technical/sales staff available to provide telephone support.

They have a fleet of modern vehicles including HIAB equipped flatbeds for speedy transport, handling and on-site support.

Contact IBS if you would like a site visit or want to discuss a project with an engineer either in person or via telephone.

New, Reconditioned and Service exchange Hire Equipment from IBS

Industrial Blower Services offer a simple and effective portable air conveying system for cleaning, recycling, collecting waste and split product. IBS offer you comprehensive solutions including Robuschi Vacuum Pumps for vacuuming wet and dry spillage and dust using their extensive industrial vacuum loaders.

Heavy Duty High Performance Industrial Vacuum Loaders are able to collect a range of materials including fine particles through to aggregates up to 50 mm in size, the unit has a maximum loading rate of 3 tons per hour over 40 meters or further if utilised with a vacuum interceptor skip and fixed pipework system. No obligation site surveys.

IBS are proud IBS are proud UK & US agents for Elmo Rietschle and RVS Liquid Ring Vacuum Pumps many other established high-quality equipment.

IBS have liquid ring, rotary vane, side channel, claw and roots type vacuum pumps available to minimise our customer's downtime in the event of:

- Emergency breakdown

- Planned repair/maintenance

- Short-term demand

- Testing of new systems

- Accidental damage

IBS Provide a Full Service and Maintenance Service for HV Turbo Blowers

IBS offer the industry comprehensive solutions for Industrial Blowers hire - wet and dry spillage and dust through the use of their extensive industrial vacuum loaders & portable vacuum units. They offer some of the industries highest quality, robust effective vacuum booster equipment and portable air conveying system for cleaning, recycling, collecting waste and spilled product.

Many industries are heavily dependent on the efficient operation of their road tanker equipment which IBS experienced staff ensure downtime is kept to a minimum. They analyse problems, advise on the most cost-effective/efficient solution and how quickly that solution can be implemented. For site emergency situations during working hours, they aim to respond within 4 hours based on distances up to 100mile radius from the nearest available engineer.

IBS is the sole European distributor of Fuitland Vacuum pumps (Road Tanker Equipment). As manufacturers, they supply all models to meet specific requirements.

All models can be supplied in either clockwise or counter-clockwise rotation. Most with 4-way valves on the top or side with optional pullout, stainless steel filter. Most can be supplied with options to mount angle gear box or hydraulic motor directly to pump.

Keep your road tanker equipment in excellent condition with IBS

-large.jpg) Offering a variety of engineering services makes IBS a versatile one-stop-shop providing convenience to clients, as well as quality products. Services include processing engineering services, repairs, servicing and recondition of blowers, vacuums and pumps which can be done both on and off-site, site surveys and fault finding, metal spray painting and equipment hire of various shaft and blower sets, vacuum pumps and portable vacuum units.

Offering a variety of engineering services makes IBS a versatile one-stop-shop providing convenience to clients, as well as quality products. Services include processing engineering services, repairs, servicing and recondition of blowers, vacuums and pumps which can be done both on and off-site, site surveys and fault finding, metal spray painting and equipment hire of various shaft and blower sets, vacuum pumps and portable vacuum units.