Siemens Turbomachinery HV Turbo Blowers from IBS Blowers

A good worker never blames his tools. In addition, a good worker always knows how to pick the right tools to use. Choosing the correct equipment to support your business will go a long way towards keep your business up and running and lowering the risk of downtime. From the very moment that your vacuum pumps fails to operate correctly, your business starts losing money. Industrial Blower Services provides an extensive collection of Siemens Turbomachinery HV Turbo Blowers; industrial vacuums and Robuschi Liquid Ring Vacuum Pumps high quality, at affordable prices, so that of all of the aspects of your business that you have to concern yourself with, failing equipment is not one of them.

Vacuum technology is synonymous with the Industrial, Utility, Manufacturing, and Municipal sectors of industry used for a number of varied and specified industrial applications. IBS’s industrial and engineering experts in vacuum technology and its respective applications, can advise you as to what specific type of equipment would work best for your company and which applications and processes would most benefit from the utilisation of this equipment.

Dedicated staff at IBS have years of experience in the manufacturing, chemical and other industries and so know from first-hand knowledge what works best in which environment. IBS experts can assist customers in making that critical decision of which equipment would be the most suitable for their needs to maximise operations, optimising costs and effectively resulting in a positive return on investment. IBS is renowned for stocking a large range of superior makes and models of vacuum pumps and blowers, chosen by well-known brands to be their sole-provider of certain products in the UK. IBS will also never sacrifice quality to save costs however will always be able to offer a suitable alternative for those who may be in need of assistance, where budget considerations can be made. Customers can revert to the engineers at IBS for advice from everything regarding maintenance and repairs, servicing, evacuation times, vacuum levels and volumes, to blower spares and ancillaries, to operational costs and environmental aspects.

Initially named the “water ring pump” the liquid ring vacuum pump is used for creating vacuum in moist gases and vapours. Typically utilised in the chemical industry, liquid ring vacuums, like many other vacuum systems, operate on the principle of positive displacement of liquid, channelling the liquid in a piston-like fashion to achieve displacement. Operating a relatively low temperatures liquid ring vacuum pumps are ideal for the condensation of vapours essentially allowing them to function, in part, as condensers, drastically reducing volume. Adaptable in that they are able to fit the medium which is being pumped, the liquid ring pump offers excellent benefits in that the lower operational temperatures, allows for the successful for the pumping of polymers which are especially temperature sensitive and prove to be far less problematic when involved in the pumping of the more volatile materials.

RVS Liquid Ring Vacuum Pumps

The RVS series comprises single stage block model machines. They are used in the fields of sterilisation, concentration, dying, impregnation, plastic extrusion, degassing and extraction of non-condensable gas from condensers in the chemical, pharmaceutical, food, pulp and paper, sugar and textile industries in addition to applications in power plants and hospitals.

The RVS series has the following key features.

- Vacuums up to 33 mbar A

- Suction capacity up to 4200 m3/hour

- Able to pump gasses and vapours

- No lubricant in contact with the pumped gasses

- Able to work in numerous applications with appropriate choice of construction materials and service fluid

RBS/AV Vacuum Boosters

The RBS/AV positive displacement machines are utilised as boosters to increase vacuum levels when used in series with a primary vacuum unit.

Typical fields of application include automotive, food, pharmaceutical, chemical, electronic and aerospace industries and power plants.

The RBS/AV series has the following key features.

- Vacuum levels of 0.01 to 20 mbar absolute

- Suction capacities from 300 to 8800 m3/hour

- Able to pump gasses and vapours

RB-DV Pre-inlet Vacuum Pumps

The RB-DV series includes tri-lobe positive displacement machines that have an atmospheric pre-injection device which reduces the heating of the gas and the power absorbed by the machine. This allows for vacuum levels up to 93% without the need for additional water injection or heat exchanger.

Typical areas of application include conveying and distribution of granulated materials in the chemical and pharmaceutical industries, de-aeration plants and centralised packaging, handling and processing machines.

The RB-DV series has the following key features.

- 93% vacuum on closed line, 90% continuous

- 840 to 10,500 m3/hour nominal capacities

- Able to pump gasses and vapours

- No oil mist

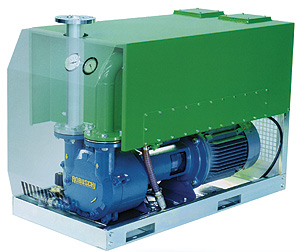

Robuschi Green Box

Environmentally friendly

An example of Robuschi innovative tradition utilising a liquid ring vacuum unit in either oil or water versions which is:

An example of Robuschi innovative tradition utilising a liquid ring vacuum unit in either oil or water versions which is:

- Compact

- Low noise

- Able to reach 15 mbar vacuum

- Ready for use

- Minimum maintenance

Siemens Turbomachinery HV Turbo Blowers

IBS are very aware of the disruption caused by blower downtime. Their abilities to respond rapidly to a breakdown situation and repair/refurbish damaged machines using state-of-the-art technologies are unequalled in the UK. As part of their service, they can also offer hire equipment for temporary cover whilst your machine is in our workshop.

Roots type blowers play a vital role in many processes. Applications range from pneumatic conveying of granules and powders to aeration of water and sewage. They are generally very reliable machines but when worked very hard they may breakdown.

IBS hold the largest range of new, reconditioned and service exchange Siemens Turbomachinery HV Turbo Blowers in stock ready for immediate dispatch, unlike most manufacturers who specify an 8 to 16 week lead time for new blowers.

IBS Suppliers of; new Siemens Turbomachinery HV Turbo Blowers, reconditioned and service exchange Siemens Turbomachinery HV Turbo Blowers and provide a full service and maintenance service for HV Turbo Blowers.

With an experienced team of professionals we are confident of providing the most cost-efficient solution to Industrial blower problems and requirements.

IBS flexibility allows them to supply and install any make and model of blower (including new innovations) for any form of contract including Framework Agreements.

IBS is a Solberg Distributor of Solberg Blower in the UK

Inlet Filter Silencers for Blowers & Compressors

Filter Silencers for filtering and noise reduction on the inlet of Compressors and Blowers.

Silencers for Blowers & Compressors

Silencer Base Frames for P.D. Blower packages, Tubular Silencers for the intake of Blowers & Compressors and Discharge Silencers for Scroll Compressors.

Inlet Vacuum Pump Filters

Inlet Filters for the inlet of Vacuum Pumps, Vacuum Pump systems and P.D. & Regenerative Blowers

Oil Mist Eliminators for Vacuum & Power Gen

Oil Mist Eliminators for the removal of mist, vapor and smoke from Vacuum Pumps, Crankcases, Turbines and Reciprocating Engines.

Specialty Applications

Specialty Applications including Extreme Duty Filtration, Photovoltaic Vacuum Filters, Liquid Removal Filters, ASME/PED Vessels, ATEX Assemblies and Separators.

Intake Filters

Inlet Filters for the inlet of Vacuum Pumps, Vacuum Pump systems and P.D. & Regenerative Blowers

Filter Elements

Replacement Air Filter Elements for standard Solberg filter assemblies and for non-standard filter sizes.

Coalescing Air/Oil Separator Elements

Replacement Coalescing Oil Mist Elements for Vacuum Pump, Compressors and Power Gen Oil Mist Eliminators.

Parts/Accessories

Replacement Parts & Accessories

FREE VACUUM LOADER HEALTH CHECK FROM IBS

Industrial Vacuum Loader and systems are widely used in Industrial, Utility, Manufacturing, and Municipal sectors. Typical areas of application include:

• Sewage treatment

• Production - Chemical, pharmaceutical, plastics, food, pulp, paper, electronics, and textile

• Power plants

• Packaging

• Conveying

• Printing

• Medical

IBS offer a wide range of Industrial Vacuum Services as well as Industrial Vacuums and Vacuum Loader either new, reconditioned or service exchange representing all of the popular, tried and tested technologies including liquid ring, rotary vane (oil lubricated and dry running), side channel, roots types (including boosters) and claw. We support all of the main manufacturers including: aerzen blowers USA, Robuschi, Busch, Becker, Rietschle, Edwards, Leybold, Siemens turbomachinery , Gast, FPZ, Nash, Sihi, Speck and Elmo.

KEEP YOUR VACUUM LOADER HEALTHY WITH A FREE HEALTH CHECK FROM IBS

Service Exchange - If you cannot afford the time for IBS to repair your vacuum pump they will forward a reconditioned unit immediately to minimise your downtime. Upon receipt of your old machine, providing it is in serviceable condition, IBS will charge for the replacement at the service exchange value. If your vacuum pump is not serviceable, IBS will upgrade your purchase to reconditioned status.